HOW TO CHECK TORQUE ACCURACY OF DC NUTRUNNER

HOW TO CHECK TORQUE ACCURACY OF DC NUTRUNNER

Now we introduce our main factor of concern in every assembly project i.e. accuracy of tool to be used in assembly for torquing. By tool accuracy, we mean the accuracy which tool produces the thing it’s supposed to produce. Tool accuracy matters because now everyone is very conscious about maintaining the quality of the product which they are producing & for which they are buying the tightening tool. But sometimes it's very difficult to understand that DC nutrunners are working properly or not means they are working in their mentioned accuracy or not i.e. ±3% or ±5%. Now we have to understand the basic role of the joint who creates everything like first, we talk about “Residual Torque”. Residual torque means the torque you are getting or checking (through a torque wrench) in the joint after fastening. So if you are working on a Soft joint means the joint with a rubber gasket or plastic then you will get less torque than your target torque & if you are working on a hard joint means the joint having metal to metal contact then you will get same torque or sometimes more torque than target torque.

Note that anything that reduces the preload or service tensions in the bolts also reduces the all-important clamping force on the joint, making it less than our ideal or target torque. Anything which increases the preload or tension means more tensile strength in the bolt than is “ideal”. But sometimes it is very difficult for a customer to understand, they simply doubted your product. So we now talk about two testers of “YOKOTA” for ensuring that the DC tool which you are using for assembly is working properly or not.

Now we introduce our main factor of concern in every assembly project i.e. accuracy of tool to be used in assembly for torquing. By tool accuracy, we mean the accuracy which tool produces the thing it’s supposed to produce. Tool accuracy matters because now everyone is very conscious about maintaining the quality of the product which they are producing & for which they are buying the tightening tool. But sometimes it's very difficult to understand that DC nutrunners are working properly or not means they are working in their mentioned accuracy or not i.e. ±3% or ±5%. Now we have to understand the basic role of the joint who creates everything like first, we talk about “Residual Torque”. Residual torque means the torque you are getting or checking (through a torque wrench) in the joint after fastening. So if you are working on a Soft joint means the joint with a rubber gasket or plastic then you will get less torque than your target torque & if you are working on a hard joint means the joint having metal to metal contact then you will get same torque or sometimes more torque than target torque.

Note that anything that reduces the preload or service tensions in the bolts also reduces the all-important clamping force on the joint, making it less than our ideal or target torque. Anything which increases the preload or tension means more tensile strength in the bolt than is “ideal”. But sometimes it is very difficult for a customer to understand, they simply doubted your product. So we now talk about two testers of “YOKOTA” for ensuring that the DC tool which you are using for assembly is working properly or not.

YOKOTA STATIC TESTER

We introduce YOKOTA STATIC TESTER, First we will check “STATIC TORQUE” of the tool on STATIC TESTER means we set the tool target torque & check it on this tester (just for setting the target value ). These testers are frictionless joints. Although we are using the DC tool means we can set target torque through software or through controller but for double-checking we use these testers. These testers are available from 5 to 1000Nm. The model starts from YET-501C, YET-10001C and all.

We introduce YOKOTA STATIC TESTER, First we will check “STATIC TORQUE” of the tool on STATIC TESTER means we set the tool target torque & check it on this tester (just for setting the target value ). These testers are frictionless joints. Although we are using the DC tool means we can set target torque through software or through controller but for double-checking we use these testers. These testers are available from 5 to 1000Nm. The model starts from YET-501C, YET-10001C and all.

FEATURES

- Larger digital display

- Measuring time can be set by every 0.1 sec within 9.9 sec.

- Able to measure in both right & left direction.

- High PRECISION withing R.O.±0.5% (static load)

- Protective cover on the front panel

- Easy to measure

- Automatic Pulse counter (counting blow number) is built-in

YOKOTA DYNAMIC TESTERS

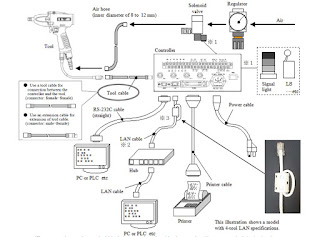

These testers are for proving the DC nutrunners that they are giving right torque or not, the torque they applying is coming in mentioned accuracy or not. So these testers are the mid part of your tool & socket you are using as shown in the picture. So these testers have a special feature that you can check both the pulse & direct mode tool. So you can check the accuracy of your tool by simply run the tool & matches the torque value of your controller & Yokota dynamic tester. These testers tell you the dynamic torque. Dynamic torque means the torque which the tool is giving on the joint during fastening. These are available from 2.8 to 250Nm. The model starts from YTT-100, Yet-250 and all.

FEATURES

- Torque display (digital three-digit indication)

- Response frequency 0 to 1.4KHz

- Provided terminals (Printer output, RS232C output, waveform detection output)

- Zero adjustments (automatic zero adjustments)

- Built-in Electric buzzer

These testers are for proving the DC nutrunners that they are giving right torque or not, the torque they applying is coming in mentioned accuracy or not. So these testers are the mid part of your tool & socket you are using as shown in the picture. So these testers have a special feature that you can check both the pulse & direct mode tool. So you can check the accuracy of your tool by simply run the tool & matches the torque value of your controller & Yokota dynamic tester. These testers tell you the dynamic torque. Dynamic torque means the torque which the tool is giving on the joint during fastening. These are available from 2.8 to 250Nm. The model starts from YTT-100, Yet-250 and all.

FEATURES

- Torque display (digital three-digit indication)

- Response frequency 0 to 1.4KHz

- Provided terminals (Printer output, RS232C output, waveform detection output)

- Zero adjustments (automatic zero adjustments)

- Built-in Electric buzzer

Comments

Post a Comment