Snug Torque - Yokota - Microntech Engineers

SNUG TORQUE - Yokota

In today’s blog topic the discussion will be about the snug point when the bolt is tightened and its significance in bolt tightening.

Bolting joints are one of the most commonly used methods to join various parts together in construction and machines. They consist of bolts that hold and join other parts and are secured with the interlinking of the threads of bolt and nut.

There are two main types of bolted joint designs like in the tension joint, the joint should be designed such that the clamp load is never overcome by the external tension forces acting to separate the joint. If the external forces override the clamp load then the clamped joint will separate, allowing the free movement of the part which is not a part of bolting a joint.

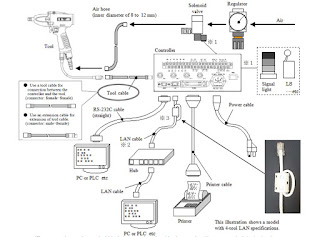

There are various torque control methods for tightening the bolts each method uses a different technique and control factors to achieve the proper tightening. These tightening methods are: -

- Torque Control

- Torque control age monitor

- Angle control

- Torque or angle control

- Torque and angle control

Snug torque is a point which occurs when there is also control of angle alongside the torque. The snug torque or point is a terminology related to tightening bolts and it can be defined as the torque required to pull the joints part together so there would be direct contact between their surface. The snug torque is used mostly in the angle control tightening method in which the tightening is done with the angle in control and the torque is not a main factor in the tightening.

The snug torque ensures that the contact between metal surfaces of the joint. The snug torque is the point for where the final angle of rotation is starting to measure and to ensure the bolt is tightened properly.

In case you want to learn more about Torque concepts you can contact Microntech for a training seminar that happens every month. If interested you can contact the nearest Microntech branch by emailing at sales@microntechgroup.com and also see our global assembly solution offering at www.microntechgroup.com.

Comments

Post a Comment