How to check if your pulse tool needs servicing

How to check if your

pulse tool needs servicing

YOKOTA

impulse wrenches are widely used for tightening jobs in the assembly industry,

where accurate torque tolerances are necessary. Impulse tools are light,

powerful, small and very importantly, have no kick-back. Evaluation of

tightening processes in car assembly shows that tightening joints uses 10% of

the total assembly time. Working with faster tools, therefore, can speed up

assembly lines substantially.

The pulse unit of the tool is used to generate the torque or power on the tool such that toque can achieve to a certain range of the tool. Due to this pulse unit, vibration becomes very minimal and the operator can use the tool by holding through a single hand at a certain torque limit.

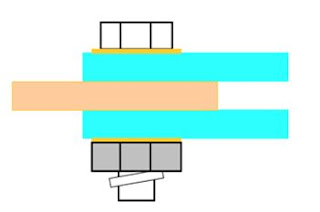

Impulse wrenches have a twin blade impulse mechanism for sealing oil which gives high repeatability. The mechanism is designed so that the liner, rotated by the air motor gives an equal torque on both blades and instant rotation torque on the main shaft (see figure below). A by-pass is designed in the liner so that the oil can escape from the area of high pressure to the area of low pressure at the moment of creating a pulse and the amount of oil flow can be adjusted by the relief valve to control the torque output. Depending on the model and setting, the impulse wrenches give 10 - 40 impulses per second. The power is transmitted by oil pressure and therefore the impulse wrenches have very low noise and vibration level.

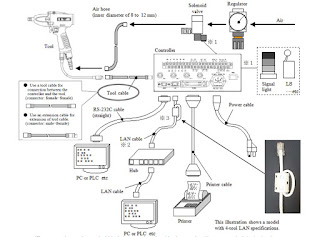

Impulse wrenches have a twin blade impulse mechanism for sealing oil which gives high repeatability. The mechanism is designed so that the liner, rotated by the air motor gives an equal torque on both blades and instant rotation torque on the main shaft (see figure below). A by-pass is designed in the liner so that the oil can escape from the area of high pressure to the area of low pressure at the moment of creating a pulse and the amount of oil flow can be adjusted by the relief valve to control the torque output. Depending on the model and setting, the impulse wrenches give 10 - 40 impulses per second. The power is transmitted by oil pressure and therefore the impulse wrenches have very low noise and vibration level. The basic configuration of the tool:-

There can be many problems that occur if the tool having a certain toque range, but the tool is not able to achieve that range and taking many pulses, taking many pulses means the tool is trying to reach the target value of the toque set. Reasons behind this more pulses can be:-

1. Effect of oil filling of pulse unit: - Pulse unit must have a proper amount of oil-filled if there will be uneven oil in the pulse unit, the tool will not be able to reach the target torque and take many pulses to reach there. Basically, if tightening is completed within 8 – 12 pulses then our tightening is perfect.

1. Effect of oil filling of pulse unit: - Pulse unit must have a proper amount of oil-filled if there will be uneven oil in the pulse unit, the tool will not be able to reach the target torque and take many pulses to reach there. Basically, if tightening is completed within 8 – 12 pulses then our tightening is perfect.

2. Effect of air pressure: - There is a main role of pressure in pneumatic tools. It gives the main power to run the tool. Normally tool requires constant 4 – 6 bar pressure to run the tool. But due to somehow if the pressure of air is not sufficient or within this range, the tool gives many pulses to reach the toque and also it affects the accuracy of the tool.

3. Effect of leakage in the airline: - Due to leakage there may but an uneven drop of torque that can happen and the tool took much time to reach the set torque.

4. Effect of more tools online and less horsepower of compressor: - This is also a critical situation of the tool if there is not sufficient power back up to reach the tool at set toque. Power backup must be needed very powerful so that the tool can get a constant and sufficient supply of air.

So, if there is any problem facing this effects the tool must be needed to servicing.

Microntech is a channel partner for YOKOTA in India, having local sales and service support all over India. Microntech has a team of experts that can help you understand the torque process. It is a premier assembly solution provider in India with global experience. To know more about assembly solutions provided by Microntech please visit our website www.microntechgroup.com or you can contact your nearest Microntech branch to schedule a demo or a visit for any issues you are facing on your assembly line.

Comments

Post a Comment