How Pokayoke is ensured in Yokota System wrench

How

Pokayoke is ensured in Yokota System wrench

YOKOTA System Wrench is

a tightening tool made in Japan and very popular in terms of high tightening

speed and high accuracy. It works by air pressure, this force is what causes

the system to work; in other words, it is the power that drives the machine.

Air pressure is provided by an air compressor. This machine has a gas-powered

pump mechanism that continually forces air into a steel container tank until the

air becomes pressurized. By using this pressurized air tool works. YOKOTA

impulse wrenches are widely used for tightening jobs in the assembly industry,

where accurate torque tolerances are necessary. Impulse

tools are light, powerful, small and very importantly, have no kick-back. Evaluation

of tightening processes in car assembly shows that tightening joints uses 10%

of the total assembly time. Working with faster tools, therefore, can speed up

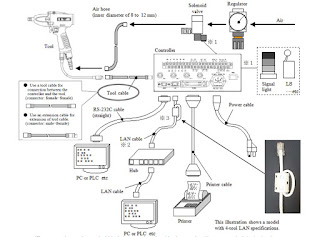

assembly lines substantially. YOKOTA System Wrench is built-in having an error-proof function after tightening completed. Every tightening gives a feedback

signal to the controller to ensure the tightening condition on the bolt. System

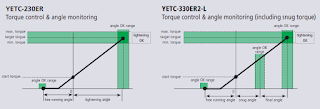

Wrench Controller have angle monitoring function which is used to detect the

movement of bolt-on tightening application and makes tightening accurate or

Poka-Yoke.

YOKOTA System Wrench is

a tightening tool made in Japan and very popular in terms of high tightening

speed and high accuracy. It works by air pressure, this force is what causes

the system to work; in other words, it is the power that drives the machine.

Air pressure is provided by an air compressor. This machine has a gas-powered

pump mechanism that continually forces air into a steel container tank until the

air becomes pressurized. By using this pressurized air tool works. YOKOTA

impulse wrenches are widely used for tightening jobs in the assembly industry,

where accurate torque tolerances are necessary. Impulse

tools are light, powerful, small and very importantly, have no kick-back. Evaluation

of tightening processes in car assembly shows that tightening joints uses 10%

of the total assembly time. Working with faster tools, therefore, can speed up

assembly lines substantially. YOKOTA System Wrench is built-in having an error-proof function after tightening completed. Every tightening gives a feedback

signal to the controller to ensure the tightening condition on the bolt. System

Wrench Controller have angle monitoring function which is used to detect the

movement of bolt-on tightening application and makes tightening accurate or

Poka-Yoke.

YOKOTA System Wrench is

a tightening tool made in Japan and very popular in terms of high tightening

speed and high accuracy. It works by air pressure, this force is what causes

the system to work; in other words, it is the power that drives the machine.

Air pressure is provided by an air compressor. This machine has a gas-powered

pump mechanism that continually forces air into a steel container tank until the

air becomes pressurized. By using this pressurized air tool works. YOKOTA

impulse wrenches are widely used for tightening jobs in the assembly industry,

where accurate torque tolerances are necessary. Impulse

tools are light, powerful, small and very importantly, have no kick-back. Evaluation

of tightening processes in car assembly shows that tightening joints uses 10%

of the total assembly time. Working with faster tools, therefore, can speed up

assembly lines substantially. YOKOTA System Wrench is built-in having an error-proof function after tightening completed. Every tightening gives a feedback

signal to the controller to ensure the tightening condition on the bolt. System

Wrench Controller have angle monitoring function which is used to detect the

movement of bolt-on tightening application and makes tightening accurate or

Poka-Yoke.

YOKOTA System Wrench is

a tightening tool made in Japan and very popular in terms of high tightening

speed and high accuracy. It works by air pressure, this force is what causes

the system to work; in other words, it is the power that drives the machine.

Air pressure is provided by an air compressor. This machine has a gas-powered

pump mechanism that continually forces air into a steel container tank until the

air becomes pressurized. By using this pressurized air tool works. YOKOTA

impulse wrenches are widely used for tightening jobs in the assembly industry,

where accurate torque tolerances are necessary. Impulse

tools are light, powerful, small and very importantly, have no kick-back. Evaluation

of tightening processes in car assembly shows that tightening joints uses 10%

of the total assembly time. Working with faster tools, therefore, can speed up

assembly lines substantially. YOKOTA System Wrench is built-in having an error-proof function after tightening completed. Every tightening gives a feedback

signal to the controller to ensure the tightening condition on the bolt. System

Wrench Controller have angle monitoring function which is used to detect the

movement of bolt-on tightening application and makes tightening accurate or

Poka-Yoke.

Microntech

is a channel partner for YOKOTA in India, having local sales and service support

all over India. Microntech has a team of experts that can help you understand

the torque process. It is a premier assembly solution provider in India

with global experience. To know more about assembly solutions provided by

Microntech please visit our website www.microntechgroup.com or

you can contact your nearest Microntech branch to schedule a demo or a visit

for any issues you are facing on your assembly line.

Comments

Post a Comment