DATA TRACEABILITY IN YOKOTA SYSTEM WRENCH

DATA

TRACEABILITY IN YOKOTA SYSTEM WRENCH

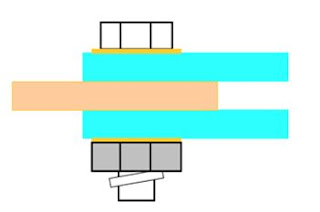

As we know

that our YOKOTA system wrench is a very unique product. It is like the DC tool with ±5% accuracy, high RPM, Torque display, count display. So they

have many other features also, like Printing the data on Printer, tightening

& Parameter data on Hyperterminal through LAN & SERIAL cross cables.

Yokota the controller also has the capability to save the tightening data. Its capacity

is 10000. They have 8 inputs & 8 output ports also for controlling the

system with socket tray, PLC, etc. We can integrate it with the conveyor line. It

is a complete POKAYOKE system. These all features are available on all the

system wrenches like Pneumatic system wrench, Electric & battery system

wrench.

TRACEABILITY

FEATURES

• Patented strain- gauge type torque transducer

• Patented angle encoder

• The onboard storage of cycle date results

• Real-time transmission of cycle data via Ethernet or Serial

• Tightening trace can be accessed and stored

• Capable of integration with plant networks, PLCs, data archival and MES System

SOME ADDITIONAL FEATURES OF CONTROLLER

• 2-way communication by RS-232

• Automatic group change (sequence programmable)

• Real-time clock

• Built-in timer (for a job)

• More input signals

• More output signals

• Can be integrated into the production any thinkable way

• (input-output signals)

• Statistics inside CP CPK

• Memory for 10.000 cycles

DATA TRACEABILITY THROUGH SERIAL

RS232C (CROSS)

Open the Hyperterminal on your PC now match the serial setting

like baud rate between Hyperterminal & controller through below commands.

Press the command “W92” in controller & now you can set the baud rate, flow, parity

and all from this command.

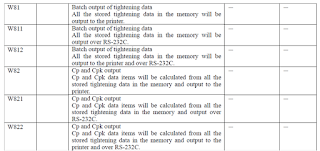

These

commands are forgotten the data on HyperTerminal.

These

commands are for setting the data length & time.

DATA TRACEABILITY THROUGH LAN

(CROSS)

Command

for LAN setting

So we can

do all the settings in the YOKOTA controller.

INPUT & OUTPUTS

HERE WE HAVE 8 INPUTS & 8 OUTPUTS

INPUT

WORKING – WHEN WE SHORT “COM” & “1N1” THEN WORKGROUP “A” WILL SELECT, SHORT

“COM” & “IN2” WORKGROUP “B” WILL SELECT & SO ON

OUTPUT WORKING – BETWEEN EVERY TWO RELAY THERE IS A “COM”. LIKE, IN

BETWEEN “RY1” & “RY2”. SO IF YOU WILL GIVE POSITIVE & NEGATIVE DC

VOLTAGE (24V) TO COM THEN IT WILL COME OUT THROUGH ASSIGNED RELAY. LIKE “RY2”

IS FOR “OK” THEN YOU WILL GET THAT VOLTAGE FROM “RY2” WHEN TIGHTENING DONE OK.

By default Output setting

• RY1 – OVER

• RY2 – OK

• RY3 – UNDER

• RY4 – FAST/SLOW ERR

• RY5 – HI

• RY6 – TOTAL OK

• RY7 – NG

Comments

Post a Comment