HISTORY OF YOKOTA INDUSTRIAL TOOLS

HISTORY OF YOKOTA

INDUSTRIAL TOOLS

Yokota

Industrial Air Tools Manufactured in their headquarters in Osaka Japan.

Yokota has a complete range of all types of air industrial tools. Yokota has

offered high-quality assembly air tools with the slogan of “Technology &

Reliability” since their establishment in 1919. Yokota first comes only with

industrial tools like air impact tools, drills, grinders, etc. But now they have a new category also, the

category is HI-TECH impulse wrenches with high durability & complete

pokayoke system.

INDUSTRIAL

TOOL HISTORY

Yokota

industrial tools include Impact wrenches, ratchet wrenches who has the composite body, high power,

durable grip, Screwdrivers like cushion clutch-type, impact type, squeezers

& hog ringers, Drills & Tappers with silencer and two-speed trigger,

electrode tip dresser, grinders, air sanders, riveting hammers, dowel pin

pullers, diamond cutters, etc. These all are the beginning products of YOKOTA.

HI-TECH IMPULSE WRENCHES

HI-TECH IMPULSE WRENCHES

Yokota

firstly invented Y & YX series tools who have the Cylinder eccentric &

Plate eccentric motor torque range up to 500Nm. Then came with YLa (non-shutoff)

& YLT (Shutoff) series who has various advantages over impact tools.

some

of these are the following :

• Maintenance cost saving

• Higher motor efficiency

• Less oil mist

• Life is double

• Better ergonomics

YLa series are available up to 160Nm with 6500 Rpm & the YLT series is available up to 210 Nm. With 6000Rpm.

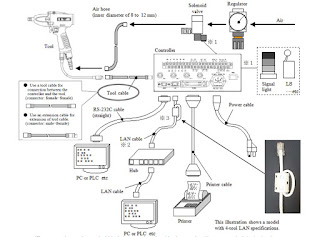

- POKAYOKE CONTROLLER

Yokota then invented the Pokayoke controller who is compatible with impulse wrenches for better controlling. Some of the features of this controller are mentioned below :

• OK & NG signal is possible

• Bolt Number display possible

• Monitoring & processing of pulsing time, pulse number and pulse wave height for high accurate tightening

• Tool deterioration is possible

• Group change is possible

• Automatic group change is also possible

- TORQUE TESTERS

Torque

testers are necessary for setting the torque of impulse wrenches. Dynamic

& Static testers both are available. Dynamic for measuring the torque

during fastening & Static for checking the target torque. Static testers

are frictionless joints. Dynamic testers are available up to 250Nm. & Static

are available up to 1000Nm.

Torque

testers are necessary for setting the torque of impulse wrenches. Dynamic

& Static testers both are available. Dynamic for measuring the torque

during fastening & Static for checking the target torque. Static testers

are frictionless joints. Dynamic testers are available up to 250Nm. & Static

are available up to 1000Nm.

- SYSTEM WRENCHES

Now

we talk about the YOKOTA’s most precise & highly durable tools which Yokota

produces through their years of experiences & efforts & now they are

very famous in the market worldwide. TOYOTA & HYUNDAI are 100% using these

wrenches in their assembly in India . TATA, Ashok Leyland, Escorts, Nissan,

Honda & many more are also big users.

System wrenches are divided in Pneumatic, Electric & Cordless

wrenches.

Following

are some main features of system wrenches :

• Direct torque detection on the main shaft

• Automatic shut-off

• ±3% accuracy in Electric & Cordless system wrench

• ±5% accuracy in Pneumatic system wrench

• A built-in buzzer or LED indication

• Adjustable torque output

• Group Management

• Management of torque data

• Simultaneous management of four tools

• Keyboard operation

• Available up to 400Nm.

• Without any jerk operation

MICRONTECH

Microntech is the sole distributor of YOKOTA in India for many years. Microntech is well

known for “ON time service & Quality work” & customers is appreciating

this company for many years. Their headquarters is in Delhi & they have

many branches in India, present in 10 states in India and provides professional

technical and sales support to its customers. The facility in Noida UP is home

to its state of the art service facility and training center.

Yokota then invented the Pokayoke controller who is compatible with impulse wrenches for better controlling. Some of the features of this controller are mentioned below :

• OK & NG signal is possible

• Bolt Number display possible

• Monitoring & processing of pulsing time, pulse number and pulse wave height for high accurate tightening

• Tool deterioration is possible

• Group change is possible

• Automatic group change is also possible

- TORQUE TESTERS

Torque

testers are necessary for setting the torque of impulse wrenches. Dynamic

& Static testers both are available. Dynamic for measuring the torque

during fastening & Static for checking the target torque. Static testers

are frictionless joints. Dynamic testers are available up to 250Nm. & Static

are available up to 1000Nm.

Torque

testers are necessary for setting the torque of impulse wrenches. Dynamic

& Static testers both are available. Dynamic for measuring the torque

during fastening & Static for checking the target torque. Static testers

are frictionless joints. Dynamic testers are available up to 250Nm. & Static

are available up to 1000Nm.- SYSTEM WRENCHES

Now

we talk about the YOKOTA’s most precise & highly durable tools which Yokota

produces through their years of experiences & efforts & now they are

very famous in the market worldwide. TOYOTA & HYUNDAI are 100% using these

wrenches in their assembly in India . TATA, Ashok Leyland, Escorts, Nissan,

Honda & many more are also big users.

System wrenches are divided in Pneumatic, Electric & Cordless

wrenches.

Following

are some main features of system wrenches :

• Direct torque detection on the main shaft

• Automatic shut-off

• ±3% accuracy in Electric & Cordless system wrench

• ±5% accuracy in Pneumatic system wrench

• A built-in buzzer or LED indication

• Adjustable torque output

• Group Management

• Management of torque data

• Simultaneous management of four tools

• Keyboard operation

• Available up to 400Nm.

• Without any jerk operation

MICRONTECH

Microntech is the sole distributor of YOKOTA in India for many years. Microntech is well

known for “ON time service & Quality work” & customers is appreciating

this company for many years. Their headquarters is in Delhi & they have

many branches in India, present in 10 states in India and provides professional

technical and sales support to its customers. The facility in Noida UP is home

to its state of the art service facility and training center.

Company goal

is to add value to the customers with the most innovative assembly solutions and

help them to use less while accomplishing more. Microntech has over 30 years of

experience with a proven track record for success. Microntech technical

engineers are able to assist with complete assembly applications. They are

recognized as technical experts for assembly solutions across India. At

Microntech, their mission is to provide high-quality assembly solutions and a

high degree of responsiveness to empower our customers to be more productive,

build a better quality product, and maintain a safe environment for their

workers

Comments

Post a Comment