Microntech Yokota Grinder with durable Grinding wheel

Microntech Yokota Grinder with durable Grinding wheel

The pneumatic grinder can be

defined as a powerful tool used for grinding or we can say abrasive cutting and

polishing metal workpiece. The main function of the pneumatic grinder is to

remove the excess metal from the surface to be ground or polished.

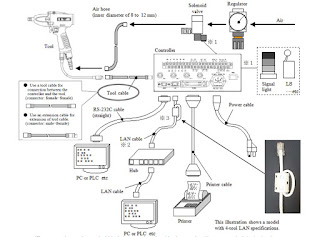

Yokota pneumatic Grinder

consists of a turbine-like rotor with vanes or blades mounted on it. The air

hose from the compressor is connected to the grinder inlet and when the tool

trigger is pressed the compressed air drives the motor. The air motor further

drives a gear mechanism (Bevel Gear) to transmit the rotating power at a right

angle to the output shaft on which the abrasive disk or grinder disk is mounted. The

abrasive disk gets worn out after several uses and can be changed very easily.

There are various kinds of discs which can be used on the grinder for different

uses, such as cut-off disc, abrasive grinding disc, grinding stones and

polishing pads.

The grinding wheel used by

Yokota in their grinder is of the best quality. The grinding wheel can be

defined as the wheel composed of an abrasive particle bonded together in the shape of the wheel which when rotated at a high speed remove the metal from the

surface.

DISC GRINDER

These are Yokota most used grinder in many

major industries because it is an advanced grinder with excellent efficiency.

The tool provides an excellent grinding operation and has ergonomics for operator handling. It can rotate up to 17000 rpm depending on the model

variant.

It

has a mechanism to change the grinding wheel effortlessly.

DISC GRINDER WITH SILENCER

These models are almost the same as the former

model but these are specially provided with a silencer to ease the operator

working condition and improve work efficiency. It can rotate up to 13000

rpm depending on the model variant.

Microntech Engineers Pvt Ltd is one of the most respected brands in India providing assembly solutions all over India and

is a preferred supplier for the YOKOTA Pneumatic/electric tools and their

Accessories in India. To contact or know more about various assembly solutions

visit their website www.microntechgroup.com or you can also contact the nearest

branch of Microntech for any trial or demo email at

sales@microntechgroup.com.

Comments

Post a Comment